Application

- residential and commercial landscaping and design

Fabrication

Viking Plastics fabricate and supply plastic planter boxes. Viking’s planter boxes are fabricated using Paneltim®, an innovative 50mm thick plastic sandwich construction panel. Viking Plastics also fabricates planter box liners, wicking beds, rain gardens, planter box water tanks and solutions to incorporate into water sensitive urban design.

DOWNLOAD BROCHURE

Bespoke Design & Finishes

Viking’s plastic planter boxes are custom made for each project. Some customers choose to clad the planters in a range of finishes* including (but not limited to):

- timber

- pressed or stamped metal panels

- decorative contact adhesive, or

- render

* Supplied by others

Australia Wide Delivery

Fabricated in Melbourne and Perth, Viking Plastics’ products are available for delivery Australia wide.

Further Information

For further information you can:

Case Studies

Case Study 1: Caribbean Park

Caribbean Park planter box

Caribbean Park planter box

Caribbean Park planter box

Caribbean Park planter box

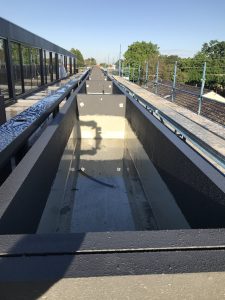

The exterior of the 16,000 square metre Jacobs Architects designed office complex at Caribbean Park incorporated 16 long planter boxes. The planters were supported by metal frames and fabricated using Paneltim® beige polypropylene, UV stabilised sandwich panels.

Each planter box is 8300mm long x 620mm wide x 540mm high. The fully welded five-sided boxes each have three internal cross braces plus two pipe braces that doubled as sling lifting tubes. The braces ensure the walls remain true when loaded with soil. The estimated weight of each planter box is 190kg. In addition, each planter box is fitted with five (5) welded penetrations for uses such as drain, irrigation conduit and architectural feature wire. The planter boxes were fabricated and delivered to site as complete individual boxes.

A multi level car park was also constructed at Caribbean Park. Viking Plastics was contracted to supply further planter boxes to create a garden wall on the car park’s facade.

Case Study 2: Hudson Apartments

Hudson Apartments planter boxes

Hudson Apartments planter boxes

For Hudson apartments, Hawthorn, Viking Plastics fabricated a range of different sized planter boxes. The builders, Crema Group, clad the Panetim® plastic planter boxes with 50mm thick styrene, recessed light fittings into the styrene and finished the outer surface with grey render.

Case Study 3: Cobuild, Walpole Street, Kew

Paneltim planter boxes were coated with rubberised render for their installation at Cobuild’s residential apartment building in Walpole Street, Kew. The Cobuild project required 35 planter boxes 2400mm (length) x 600mm (wide) x1000mm (high). The boxes were installed with spacers between each planter to allow for thermal expansion and contraction.

Caribbean Park facade commercial planter boxes Caribbean Park facade commercial planter boxes |

Hudson Apartments planter boxes Hudson Apartments planter boxes |

|

Walpole Street, Kew Walpole Street, Kew |

Walpole Street plastic planter boxes with rubberised render Walpole Street plastic planter boxes with rubberised render |

|