Grease traps are used to slow the flow of warm/hot greasy water to allow it to cool. As the water cools, the grease and oil separate and floats to the top, solids to settle on the bottom of the tank and the cleaner/cooler water flows out to sewer.

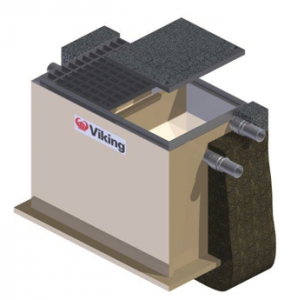

Below Ground Grease Traps

Features

- Suitable for below ground installation

- Designed to comply with local water authority specifications

- Pipe fittings are fully welded for superior seals

- Fitted with 100mm inlet and outlet and a 50mm vent plain pipe nozzles

- Access covers (sold separately) capable of being removed by one man should be fitted on top for easy access and tank cleaning

- Access covers are available in various types (concrete in-fill, solid top or tiling edge), numerous sizes and several weight loadings (pedestrian, car or truck)

Construction Options

Paneltim® Grease Traps

Below ground Paneltim® grease trap

Below ground Paneltim® grease trap

- Paneltim® below ground grease traps are a cost competitive alternative to thin skin tanks. Due to the superior strength and rigidity of Paneltim®, poured concrete reinforcement is not required thus saving time and money.

- Paneltim® is an innovative 50mm thick, dual skin sandwich panel. It has an internal cross-rib cell structure that is lightweight yet offers superior strength and rigidity in both length and width.

- Paneltim® grease traps can be backfilled with crushed rock or stabilised sand.

- Below ground grease traps must be fitted with a steel access cover* matched to the tank size and the expected load rating (pedestrian, car, heavy truck) [*metal access covers supplied separately]

Thin Skin Grease Traps

Below ground grease trap with concrete in-fill covers.

Below ground grease trap with concrete in-fill covers.

- Thin skin grease traps are fabricated from 6mm Polypropylene or Polyethylene for below ground installations.

- Thin skin below ground grease traps must be surrounded with 100mm thick (minimum) concrete walls. The tank base must be adequately supported internally to prevent collapse of the walls when concrete is being poured (concrete to be poured during installation)

- Full height keying strips are provided to ensure the plastic tank walls bind to the poured concrete. The keying strips include holes to install Y12 reinforcing bars. The reinforcing bars help to provide better binding of the steel reinforcement in the poured concrete

- External 50mm flat rim flange around the top of the tank provides a better binding surface between the tank and poured concrete and a level contact area for the access cover/s to seat

- Below ground grease traps must be fitted with a steel access cover matched to the tank size and the expected load rating (pedestrian, car, heavy truck)